First, the problem that the powder with poor fluidity is not easy to mix evenly

1. Question raising

In actual work, we often encounter very poor fluidity of the powder, according to the observation, pile powder Angle ≥40° of the powder, it becomes very difficult to mix evenly. It is almost impossible to achieve the purpose of uniform mixing by relying on the mixing equipment with only the movement of the barrel, and it is difficult to extend the mixing time.

2. Solutions

Due to the poor fluidity, the powder particles are not easily separated from the surrounding particles, so it is necessary to have forced mixing means when mixing, and repeatedly cut and displace the powder particles, so as to overcome the mixing difficulty caused by poor fluidity. Therefore, when mixing the powder with poor fluidity, a mixer with mixing blades should be selected in the mixing equipment to better complete the mixing task. Second, light and light powder is not easy to mix evenly

1. Question raising

For example, in the seasoning mix, it is necessary to mix the relatively heavy salt grains and the lighter chili powder, dried onion powder, etc., which is a typical mix of light and heavy powder. Through the liquid model of moving powder, it can be seen that in the mixing container of moving powder, because the proportion of fine and light chili powder and dried onion powder is much smaller than that of salt, MSG and other powder, it has been floating above the container, if there is no forced means, even if it is mixed for a long time, they are still difficult to mix into the main powder.

2. Solutions

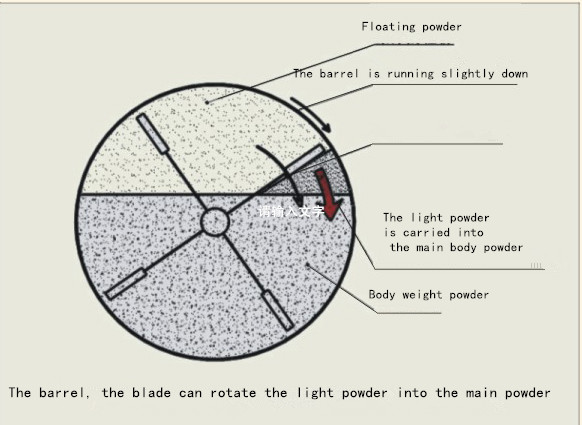

1) The choice of double motion ® mixer can solve this problem well, (as shown in the figure below) because the rotation of the double motion ® mixer container and the inner blade rotate in the same direction (the speed is not the same), so that the container and the blade will carry the light powder floating above into the main heavy powder, so that the light and light powder can be evenly mixed.

2) Through the alloy mixing index, the calculation and analysis pointed out that the index of heavy powder such as salt and MSG was too large. By grinding and refining the heavy powder such as salt and MSG, their alloy mixing index was close to that of the equilibrium value of specific gravity and average particle size became smaller than that of chili powder and shallot powder, thus reducing the difficulty of the mixing process. It is just that the cost of doing so is larger and economically not cost-effective.

Third, the problem that ultrafine powder is not easy to mix evenly

1. Question raising

Ultrafine powder usually refers to more than 1000 mesh or more than 2000 mesh powder, a specified powder to analyze, when its average particle size is small to a certain extent, its external physical characteristics will change greatly, the original will not float will float, and there will be adsorption, agglomeration and other characteristics, for such ultrafine powder mixing uniformity is particularly difficult.

This is mainly because after the particle is refined into a ultrafine powder, the original inherent gravity binding on it is significantly insignificant. Without gravity to bind its movement activity, the electrostatic effect will be prominent, which will bring difficulties to the mixing process.

2. Solutions

1) Reduce the movement speed of the mixing equipment and try to avoid the floating movement of ultrafine powder. Make the mixing equipment run at medium and low speed as much as possible to reduce the movement activity of the ultrafine powder.

2) The Dual motion ® mixing device solves this problem by using the binding effect of the joint movement of its container and blade to press the ultrafine powder floating above the container into the main powder.

When loading, the material is filled to 80% - 85% of the mixer container, which is much more in order to reduce the possibility of ultrafine powder floating and increase the pressure between the powders, which is conducive to the effect of blade shear. Fourth, the problem that the powder with trace elements is not easy to mix evenly

1. Question raising

In food, additives, medicine and other industries, products often need to add trace elements, the following difficulties exist when these trace elements are involved in mixing: 1) the amount of trace elements added is small, sometimes only 1‰, or even less; At the same time, trace elements are particularly valuable and important, and play a key role in product quality, so once trace elements accumulate in the dead corner of the barrel, it will cause product scrap.

2) Generally, the fluidity of the main powder in food, additives, medicine and other industries is poor, which brings great difficulties to the uniform mixing of extremely small amounts of trace elements.

2. Solutions

The above difficulties can be solved in the following ways:

1) The mixing method of successive increments is used to solve the problem, and the trace elements are continuously diluted to achieve the purpose of uniform mixing. For example, in a mixed task with a trace element content of 1‰, the task can be divided into three times to complete, each time in accordance with the ratio of 1:10 mixed, and finally complete the mixed task. The operation process of this method is time-consuming, laborious, many links and easy to make mistakes.

2) For the difficulty that trace elements are easy to accumulate in the dead corner of the barrel, it is necessary to use the mixing equipment that the barrel can move, so as to avoid the generation of dead corners and avoid the accumulation of trace elements in the dead corner.

3) For the difficulty of adding very little trace elements and the poor fluidity of the main powder, it is necessary to use a mixing equipment with a forced shear mixing function, so that you can overcome the difficulty of the poor fluidity of the powder, and at the same time, by repeatedly cutting trace elements, so that the mass is uniform, to achieve the purpose of uniform mixing of trace elements.

3. Mixing of powder with trace elements

It can be seen that only the mixing equipment with two mixing methods can perfectly solve the problem of uniform mixing of the powder with trace elements, and can simplify the operating procedure and mix in place at one time.

Fifth, there is a problem in the powder that false particles are not easy to mix evenly

1. Question raising

False particles are formed by small particles of powder clumping together to form larger particles - that is, false particles. There are many reasons for the formation of false particles, such as wet bonding, electrostatic adsorption, adhesion due to high temperature during processing, and so on. If the false particles are not opened and dispersed when the dry powder is mixed, the mixing effect will be affected and the quality of the final product will be affected. In order to avoid the appearance of false particles, it is necessary to have a shear force that can open and break the adhesive force between the fine powder during mixing. The single-barrel moving mixing device cannot provide such shear force when mixing, so it can do nothing about false particles.

2. Solutions

The double-motion ® mixer has full-size blades for interspersing and shearing motion, which can very well open and break up the false particles to achieve a better mixing effect. However, if the adhesive force of the fake particles is too strong, too "strong", the dual motion ® mixer can not completely break it up, then you need to use other equipment to help.