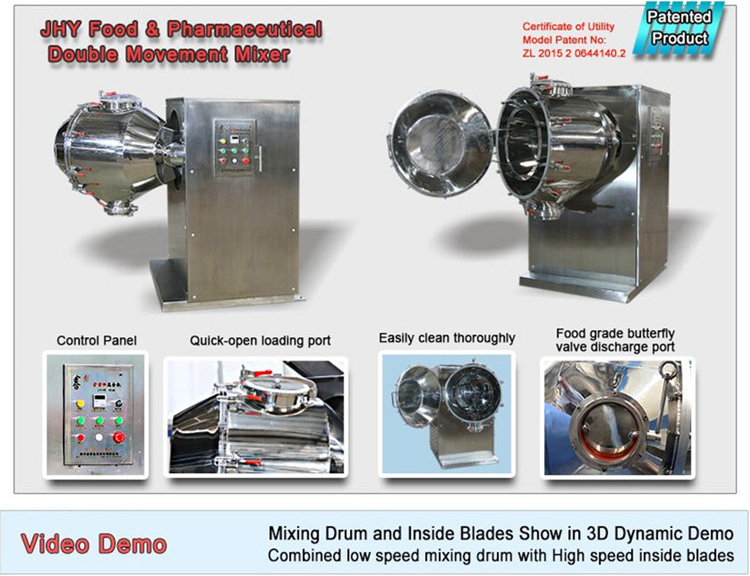

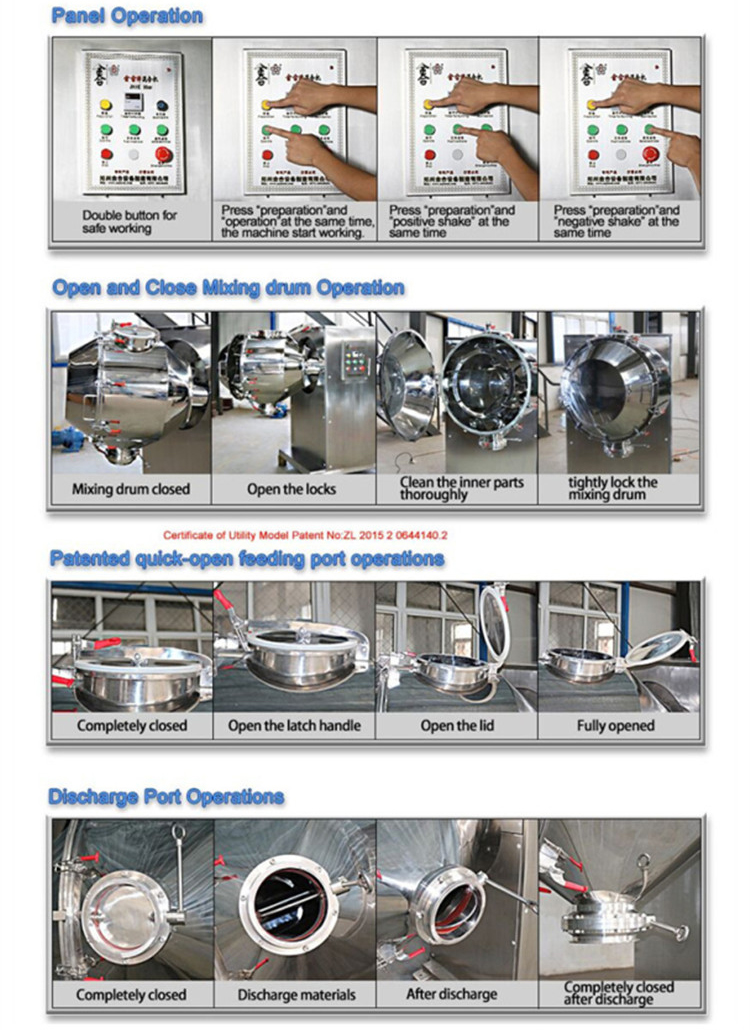

In view of the strict requirements of the food and pharmaceutical industry for internal cleaning of mixer, we have developed a JHY dual movement mixer with the unique advantage of full open door design. A particularly important advantage is that the opening and closing of the mixer barrel's door only takes less than one minute, and the opening and closing of the barrel's door can be completed in less than 20 seconds with a little training.

This excellent opening performance and the speed of opening and closing are unique in the industry in mixer equipment. This is the embodiment of our design excellence.

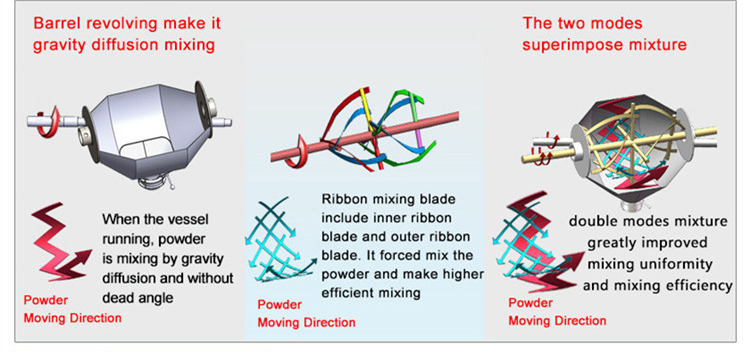

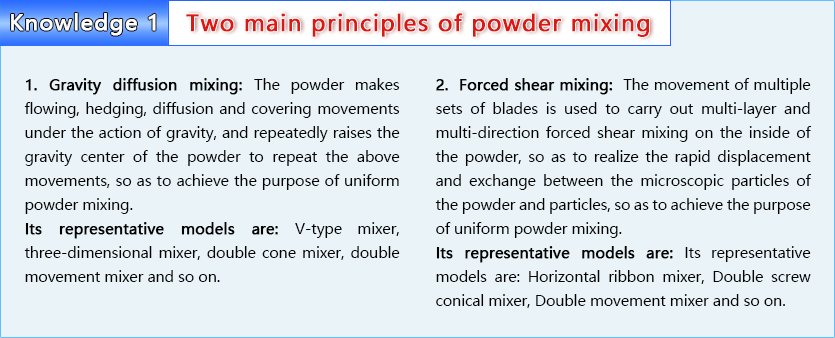

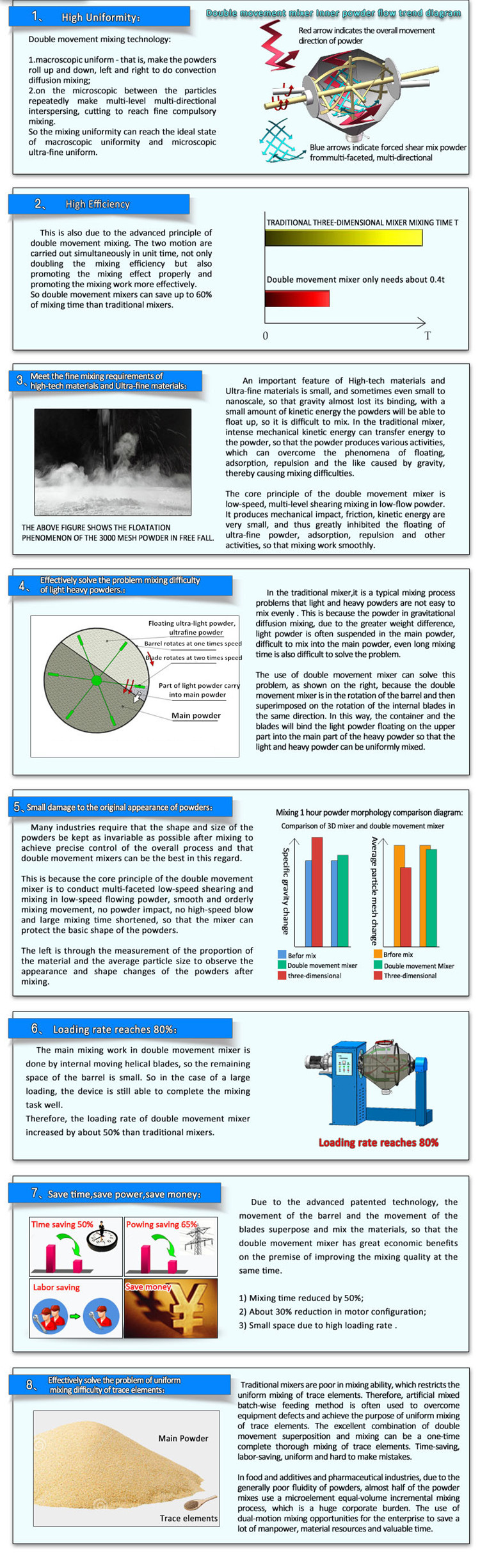

Using advanced double movement overlay mixing technology, it realizes two functions of gravity diffusion mixing and forced shear mixing on one device. It can achieve macroscopic uniformity - that is, let the powder roll up and down, left and right convection diffusion and uniform mixing; It can also repeatedly intersperse and cut between particles and particles at the microscopic level of the powder to achieve fine forced mixing.

Therefore, the mixing uniformity can reach the ideal state of macroscopic uniformity and microscopic ultra-fine uniformity.

This is also because of the advanced principle of superimposed mixing of two movements, two movements are carried out at the same time in a unit time, which not only doubles the mixing efficiency, but also promotes each other just right, and promotes the mixing work more effectively.

As a result, the dual movement ® mixer saves up to 60% of time compared to conventional mixers.

In the dual movement ® mixer, the main mixing work is done by the internal full size blades, so the remaining space of the barrel can be small. Therefore, in the case of a large loading rate, the equipment can still perform the mixing task well. As a result, the dual movement ® mixer has a loading capacity of more than 50% compared to conventional mixers.

| Model | Barrel volume(L) | Working volume(L) | Barrel speed(r/min) | Blade speed(r/min) | Motor power(kw) | Overall dimension | Machine weight(kg) |

| (L*W*Hmm) | |||||||

| JHY50 | 50 | 37.5 | 23 | 55 | 0.75 | 1189x553x1051 | 280 |

| JHY100 | 100 | 75 | 21 | 46 | 1.1 | 1412x603x1051 | 330 |

| JHY200 | 200 | 150 | 18 | 39 | 2.2 | 1771x781x1323 | 550 |

| JHY400 | 400 | 300 | 13 | 27 | 2.2 | 1970x823x1600 | 700 |

| JHY600 | 600 | 450 | 12 | 26 | 3 | 2226x978x1816 | 1100 |

| JHY800 | 800 | 600 | 11 | 23 | 4 | 2376x1023x1918 | 1300 |

| JHY1000 | 1000 | 800 | 10 | 21 | 5.5 | 2534x1100x1934 | 1500 |

| JHY1500 | 1500 | 1200 | 7.5 | 167.5 | 3032x1123x2395 | 2000 | |

| JHY2000 will base on the customers requirements | |||||||

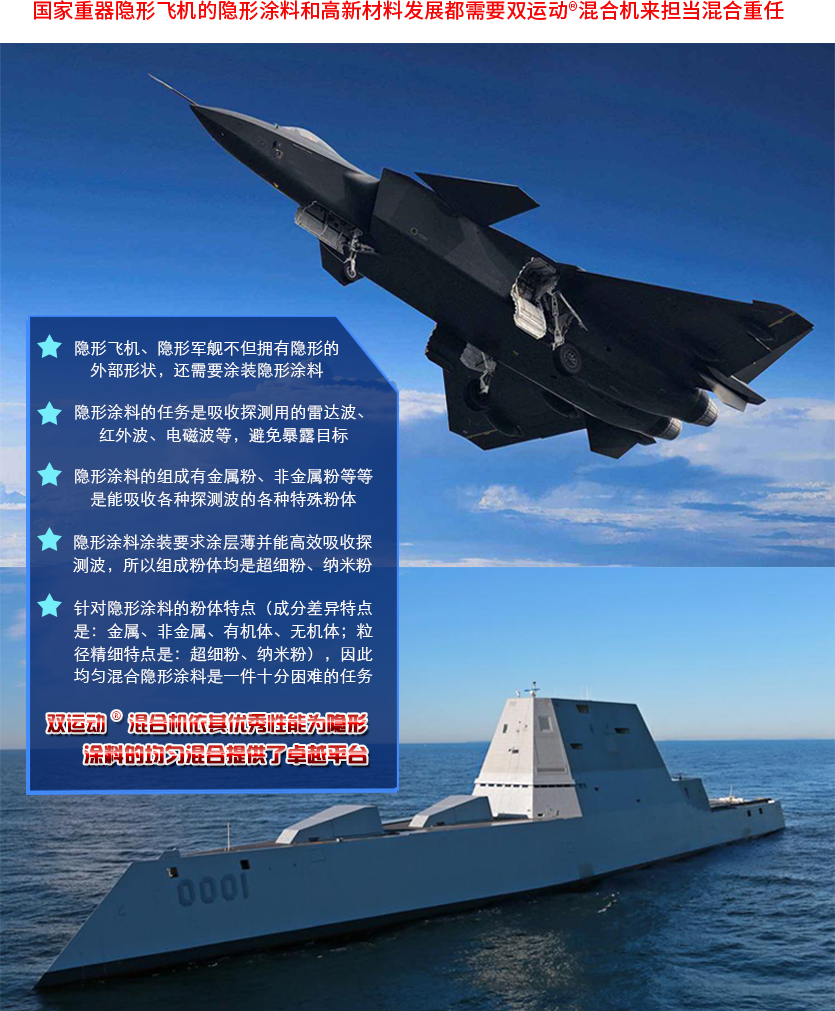

The development of stealth coatings and high tech materials for national heavy stealth aircraft all require double movement ® mixer aircraft to take on the heavy task of mixing