For many customers to mix more or less batches, the usual solution is to purchase different capacity mixers to meet these mixing requirements, therefore, a lot of procurement costs. Is there a better solution? In response to this problem, we have developed a double movement® JHN replaceable barrel model, which solves this problem well.

The purpose of the development of the JHN replaceable barrel model is to replace the different size of the barrel according to material amount on a machine, so as to solve this problem in a low cost and ingenious way.

Note: When the batch of materials is much smaller than the volume of the barrel (less than 25% of the volume of the barrel), because the material is very small, the powder pressure between the powders is very low, and it is difficult to achieve high uniformity purpose, so the material is 50%~80% of the volume of the barrel is the best ratio, which is conducive to uniform mixing.

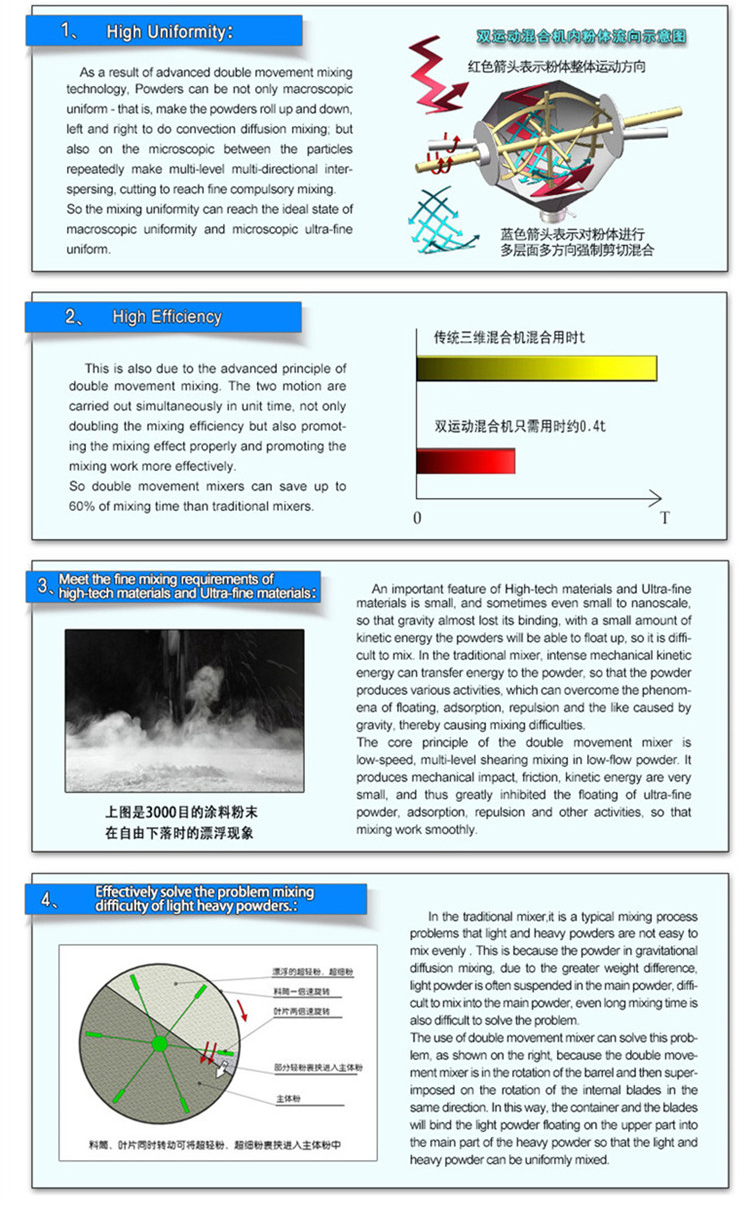

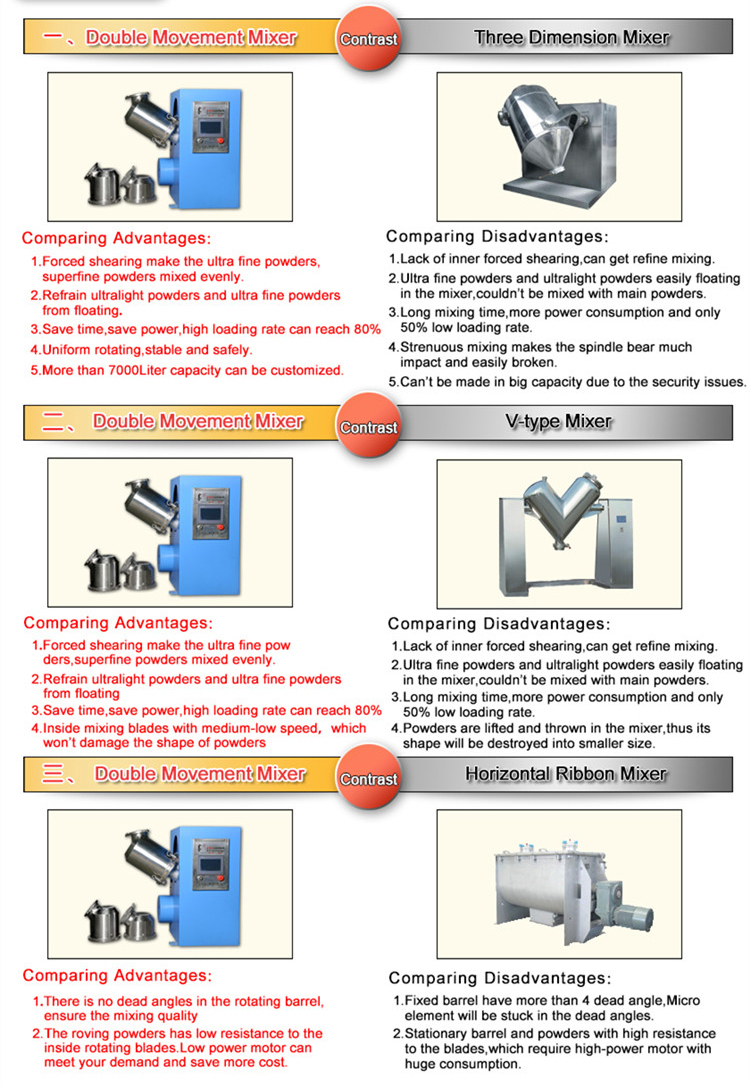

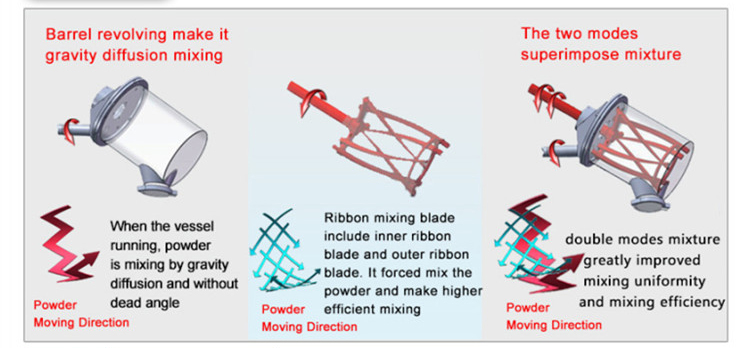

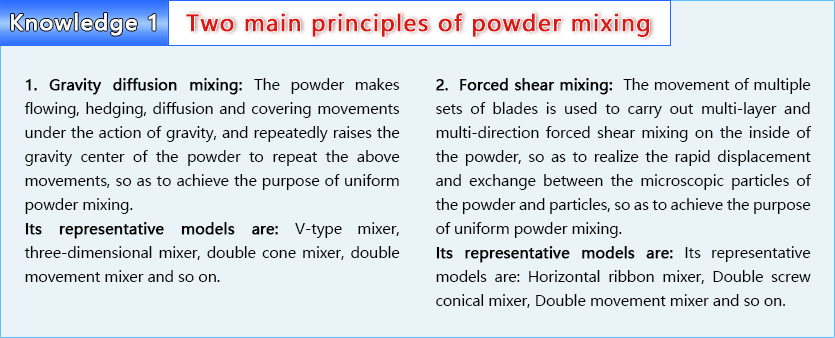

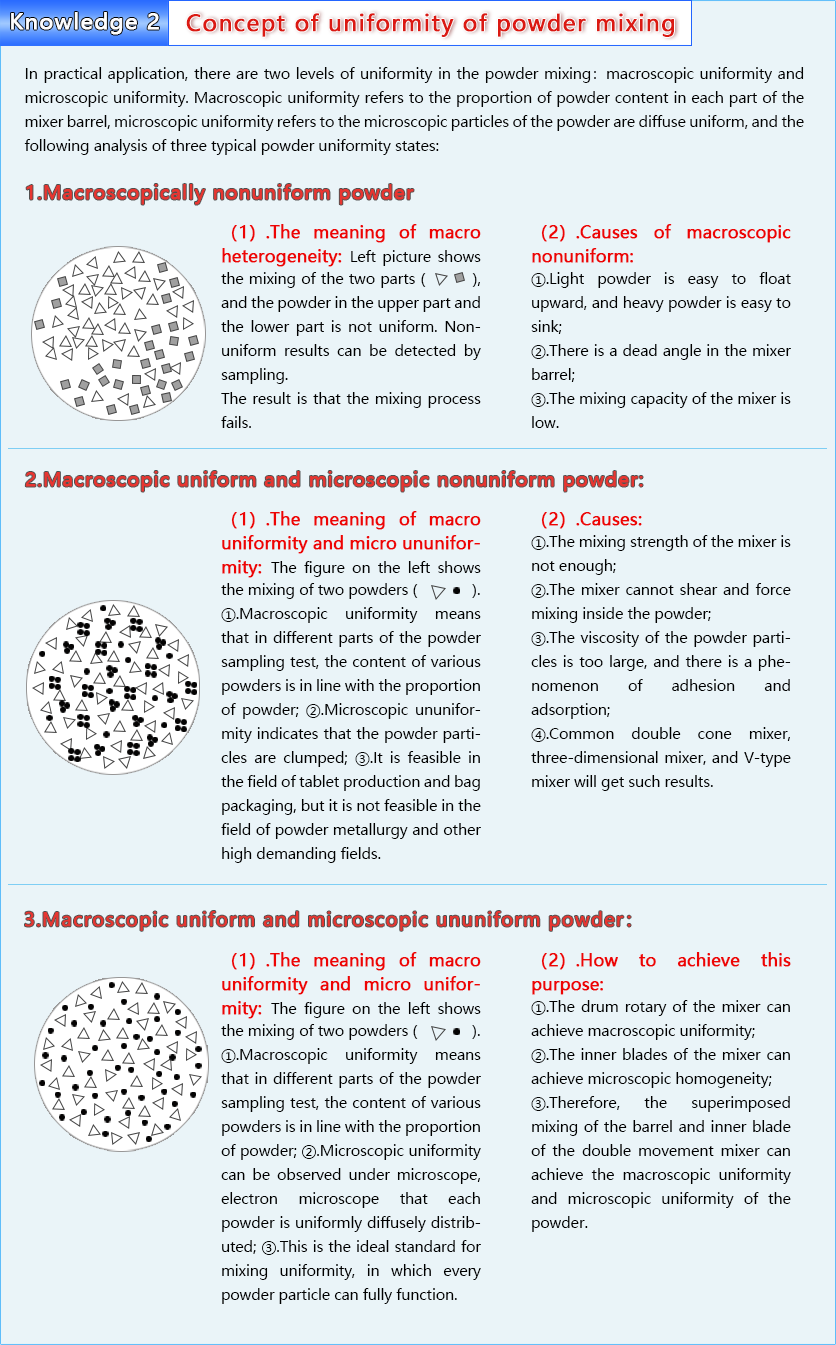

Using advanced double movement overlay mixing technology, it realizes two functions of gravity diffusion mixing and forced shear mixing on one mixer. It can achieve macroscopic uniformity - that is, let the powder roll up and down, left and right convection diffusion and uniform mixing; It can also repeatedly intersperse and cut between particles and particles at the microscopic level of the powder to achieve fine forced mixing. Therefore, the mixing uniformity can reach the ideal state of macroscopic uniformity and microscopic ultra-fine uniformity.

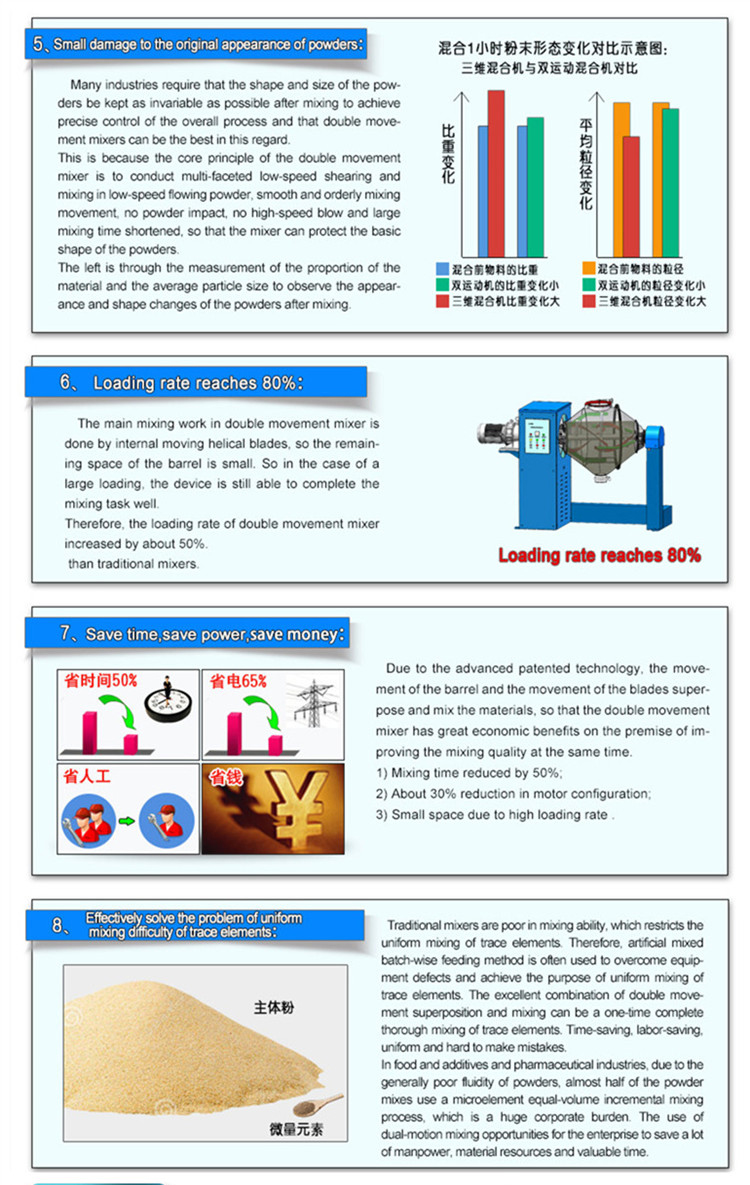

This is also because of the advanced principle of superimposed mixing of two movements, two movements are carried out at the same time in a unit time, which not only doubles the mixing efficiency, but also promotes each other just right, and promotes the mixing work more effectively. As a result, the double movement ® mixer saves up to 60% of time compared to traditional mixers.

In the double movement® mixer, the main mixing work is done by the internal full size blades, so the remaining space of the barrel can be small. Therefore, in the case of a large loading rate, the equipment can still perform the mixing task well. As a result, the double movement ® mixer has a loading capacity of more than 50% compared to traditional mixers.

Model | Barrel volume(L) | Loading rate(kg) | Barrel speed(r/min) | Blade speed(r/min) | Motor(kw) | Overall dimension |

(L*W*Hmm) | ||||||

JHN-15 | 11、15、18 | 35 | 23 | 60 | 0.37 | 1045x600x990 |

JHN-55 | 30~55Customized barrels | 60 | 22 | 55 | 1.1 | 1200x780x1250 |

JHN-110 | 60~110Customized barrels | 100 | 20 | 49 | 1.5 | 1300x820x1400 |