Fifteen years ago, before the introduction of Double movement mixer, the mainstream mixers on the market were all designed by foreigners and were all based on a single mixing principle, Their mixing performance has significant defects (such as: gravity diffusion type mixers represent V-shaped machines and three-dimensional machines, with the disadvantage of lacking sufficient shear and displacement at the micro level of the powder, resulting in low mixing efficiency; forced shear type mixers represent spiral belt mixers and single cone mixers, with the disadvantage of having dead corners of the material and slow macroscopic movement speed of the powder).

Our design team has proudly developed a double movement mixer to address the aforementioned issues, which has effectively addressed the various shortcomings of traditional mixers.

The double movement mixer has created a new mixing concept, greatly improving mixing efficiency!!!

Knowledge of Mixing Principle:

1. Gravity Diffusion type mixing principle: 2.Forced shear mixing principle:

Repeatedly raise the center of powder,use Using blades to shear powders repeated.

the power of gravity to force the powder Microscopic powders are fully displaced, thus flow,diffuse,hedge, so as to achieve achieve the purchase of Uniformity.

the purchase of uniformity.

Representative Mixers: V type mixer, 3D Representative Mixers: Ribbon Mixer,

mixer Movement Mixer

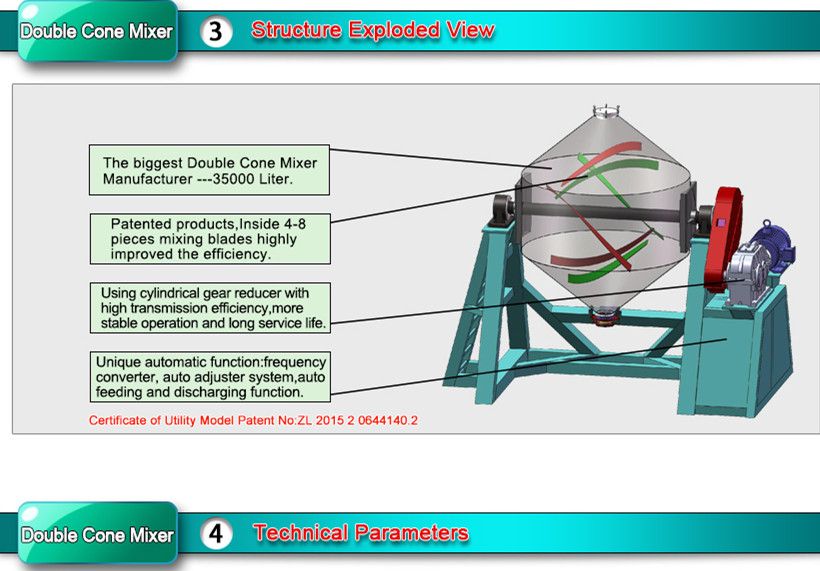

| Model | Barrel Capacity | Max Loading Capacity | Thickness | Barrel Speed | Blades Speed | Motor Power | Size |

| (L) | (L) | (mm) | (r/min) | (r/min) | (kw) | (mm) | |

| JHS2000 | 2000 | 1050 | 6 | 10 | 10 | 12 | 3100x1550x2600 |

| JHS3000 | 3000 | 1450 | 6 | 8 | 8 | 18 | 3500x1780x3000 |

| JHS5000 | 5000 | 2400 | 6 | 8 | 8 | 25 | 4100x2100x3300 |

| JHS10000 | 10000 | 6000 | 8 | 4.4 | 4.4 | 75 | 4880x3200x4407 |

| JHS15000 | 15000 | 9000 | 10 | 4.3 | 4.3 | 90 | 5384x3374x4878 |

| JHS30000 | 30000 | 18000 | 12 | 4 | 4 | 200 | 5780x3390x5833 |

| Between JHS3000~JHS35000,Any specifications can be made in private according to the specific needs of customers. Note: Due to the limitations of China's road transportation roads, the hybrid machine can achieve 35000L at present. | |||||||