High Temperature Inert Atmosphere Furnace up to 1700°C

This controlled inert atmosphere heat treatment furnace is pre-vacuumed to ensure that the oxygen content in the furnace is minimized, and then nitrogen, argon is introduced to obtain the desired heating treatment under the protection of the atmosphere. Due to its excellent atmosphere and compactness, it has been widely used in material laboratories or small batch production of semiconductors, silicon nitride, and other products.

This controlled inert atmosphere heat treatment furnace is pre-vacuumed to ensure that the oxygen content in the furnace is minimized, and then nitrogen, argon is introduced to obtain the desired heating treatment under the protection of the atmosphere.

Ⅰ. Technical Specifications | |

| Max. temperature | 1700℃ (<2hour) |

| Working temperature | 1600℃ |

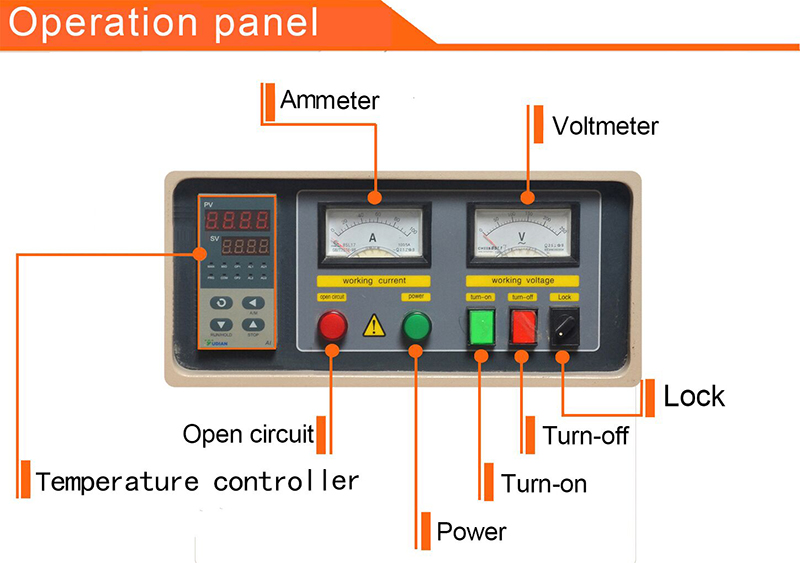

| Standard Temperature controlling | ● PID automatic control via SCR (Silicon Controlled Rectifier) power control with phase angle fired, current limiting resistor. ● 51 programmable segments for precise control of heating rate, cooling rate and dwell time. ● Built in PID Auto-Tune function with overheating & broken Thermocouple broken protection. ● Over temperature protection and alarm allows for operation without attendant  |

| Optional of Temperature controlling | ● Software (Furnace can be operated by PC by installing a control software) ● Touch screen temperature controller |

| Temperature accuracy | ±1℃ |

| Temperature Uniformity | ±5℃ over 120mm @ 1600℃ ±3℃ over 80mm @ 1600℃ |

| Heating rate | 0-15℃ /min |

| Thermocouple | B type (Pt-Rh) with 99.7% purity Alumina tube |

| Heating element | U type MoSi2 heating element |

| Furnace Chamber | Three layers of ceramic fiber insulation materials ● First layer: 1800℃ ceramic fiber board. ● Second layer: 1600℃ ceramic fiber board. ● Third layer: 1430℃ ceramic fiber board. |

| Furnace structure | Double layer steel casing with dual cooling fan, surface temperature below 60℃ |

| Furnace door | ● Power cutting off when furnace door open |

| Warranty | ● One year limited warranty with life time support. (Consumable parts such as heating elements and crucibles are not covered by the warranty, please order the replacement at related products) ● ATTENTION: Any damages caused by the use of corrosive and acidic gases are not under the coverage of One Year Limited Warranty. |

| Certifications | CE |

Ⅱ. Application Notes | |

| Using Attentions | ● Cooling rate shall also not exceed 10℃/min. ● Toxic or explosive gases are not recommended for use with this furnace without necessary safety controls and supervision. ● Small cracks may appear on the surface of the refractory ceramics over extended use. This is a normal occurrence and the cracks may be repaired with alumina coating. ● Refractory door block must be inserted before closing door. |

| Model | Max. Temp. | Chamber size | Voltage | Power |

| AS-1 | 1200℃ | 100*100*100mm | 220V | 0.8kW |

| AS-2 | 1200℃ | 120*120*130mm | 220V | 1.2kW |

| AS-3 | 1200℃ | 150*150*150mm | 220V | 2.5kW |

| AS-5 | 1200℃ | 150*150*200mm | 220V | 3kW |

| AS-8 | 1200℃ | 200*200*200mm | 220V | 5kW |

| AS-12 | 1200℃ | 200*200*300mm | 220V | 6kW |

| AS-27 | 1200℃ | 300*300*300mm | 380V | 8kW |

| AS-36 | 1200℃ | 300*300*400mm | 380V | 10kW |

| AS-64 | 1200℃ | 400*400*400mm | 380V | 16kW |

| Model | Max. Temp. | Chamber size | Voltage | Power |

| 14AS-1 | 1400℃ | 100*100*100mm | 220V | 1kW |

| 14AS-2 | 1400℃ | 120*120*130mm | 220V | 2kW |

| 14AS-3 | 1400℃ | 150*150*150mm | 220V | 3kW |

| 14AS-5 | 1400℃ | 150*150*200mm | 220V | 4kW |

| 14AS-8 | 1400℃ | 200*200*200mm | 220V | 5kW |

| 14AS-12 | 1400℃ | 200*200*300mm | 220V | 7kW |

| 14AS-27 | 1400℃ | 300*300*300mm | 380V | 9kW |

| 14AS-36 | 1400℃ | 300*300*400mm | 380V | 11kW |

| 14AS-64 | 1400℃ | 400*400*400mm | 380V | 18kW |

| Model | Max. Temp. | Chamber size | Voltage | Power |

| 17AS-1 | 1700℃ | 100*100*100mm | 220V | 1kW |

| 17AS-2 | 1700℃ | 120*120*130mm | 220V | 3kW |

| 17AS-3 | 1700℃ | 150*150*150mm | 220V | 4kW |

| 17AS-5 | 1700℃ | 150*150*200mm | 220V | 5kW |

| 17AS-8 | 1700℃ | 200*200*200mm | 220V | 7kW |

| 17AS-12 | 1700℃ | 200*200*300mm | 220V | 8kW |

| 17AS-27 | 1700℃ | 300*300*300mm | 380V | 10kW |

| 17AS-36 | 1700℃ | 300*300*400mm | 380V | 12kW |

| 17AS-64 | 1700℃ | 400*400*400mm | 380V | 20kW |

Max temperature:

1200℃ (HRE Fe-Cr-Al-Mo wire)

1400℃ (SiC Heater)

1700℃ (MoSi2 Heater)

This Inert Atmosphere Furnace is made of alumina polycrystalline fiber, and the temperature field is balanced and pollution-free.

Fully enclosed structural furnace, double-layer thickened steel plate, can bear 0.1 Mpa pressure

The top, left, right, and back are made of 12mm solid square steel for reinforcement, and the vacuum is not deformed. The maximum vacuum can be up to -0.08MPa.

Temperature controlling system of this argon atmosphere furnace adopts industrial precision 0.2-level intelligent instrument, PID adjustment, 50-segment programming.

The furnace door has the good sealing performance. Four hand wheels lock the furnace door and use the silicone ring to seal.

Furnace door fire brick (except 1200 type)

High temperature gloves; tongs; manual

Two pcs heating elements (except 1200 type)

Rotary vane vacuum pump

Direct-connected vacuum pump

Touch screen/computer connection software

Crucible (multi-layer kiln furniture)

Heating element (Sic and MoSi2)

Air system (float/proton flow meter, 2 / 3 channels of gas)