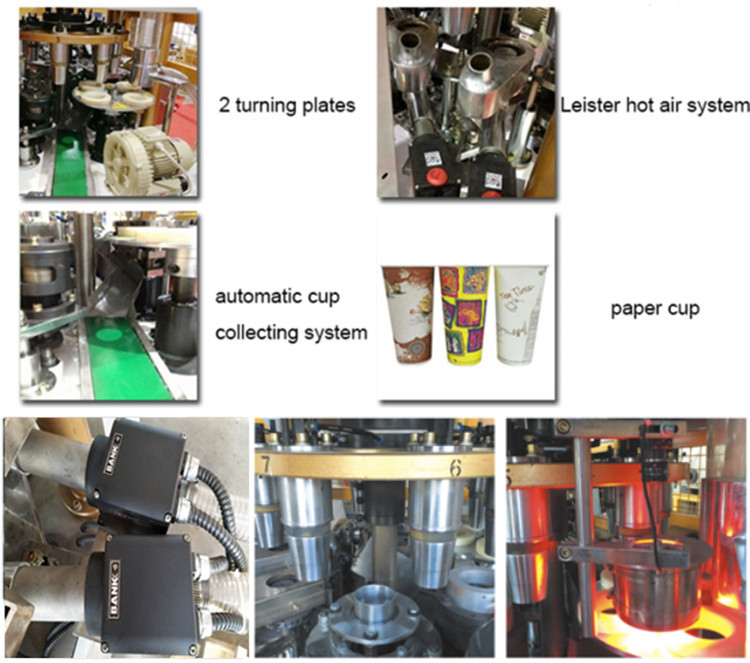

JH-C12H High speed paper cup machine, invented based on the leading technology of paper cup machine, adopting the advantages of domestic and abroad technology, is suitable for papers of any quality in the market. JH-C12H adopting the Imported Schneider inverter for driving the machine, Switzerland Leister hot air system for bottom preheating, and automatic oil lubricating system, vacuum pump for sucking down the paper, together with the automatic cup collecting system, it has realized the full automation and more efficiency.

Feature:

1.This high speed paper cup machine carries out bottom sealing by Switzerland Leister hot air system and side sealing by ultrasonic.

2.Cups of different sizes are easy to produce by changing moulds.

3.Our paper cup making machine is capable of manufacturing double PE coated paper cups suitable for cold and hot drink.

4.With our unique single-shaft bottom knurling system, low leaking ratio and high quality can be guaranteed.

5.Paper sucking system of this high speed paper cup machine uses vacuum pump with large power and stable performance.

6.With unique single shaft design and stable gear system, it would be more stable when our paper cup making machine running at a high speed.

7.With automatic lubricating system, this high speed paper cup machine will automatically lubricate every moving parts when it runs.

8.Every cam is hardened to ensure safe and stable operation.

9.Our paper cup making machine is equipped with automatic cup collecting, stacking and counting system.

10.Special pre-feeding system for bottom paper helps avoid waste.

11.This high speed paper cup machine uses Siemens PLC micro computer system and touch screen for easy and visual operation.

12.Upgraded gear box allows longer service life.

13.Optional quality control system.

Specification of JH-C12H paper cup machine:

| Model | JH-C12H |

| Material | 170g-350g single or double pe coated paper |

| Speed | 90-100pcs/min |

| Voltage | 380v 50hz |

| Air power | 0.20m³/min |

| Rated power | 11kw |

| Weight | 3000kg |

| Overall dimension | 2600mm×1300mm×1900mm |

Configurations:

| Parts | Origin |

| Inverter | Schneider |

| Button | Onpow, Chinese leading brand |

| Relay | Idec and Omron, Japan |

| Switch | Schneider |

| Main motor | 2.2kW China DASU motor |

| Knurling motor | 0.75kW China GPG motor |

| Hot air system | Leister, Switzerland |

| PLC system | Siemens |

| Touch screen | Siemens |

| Contactors | Schneider |