Introduction:

Combined parts:

•Screw Conveyor

•Auger Filler (Dynamic Weight System) with Stand on MDP Machine

• Spoon Dispenser

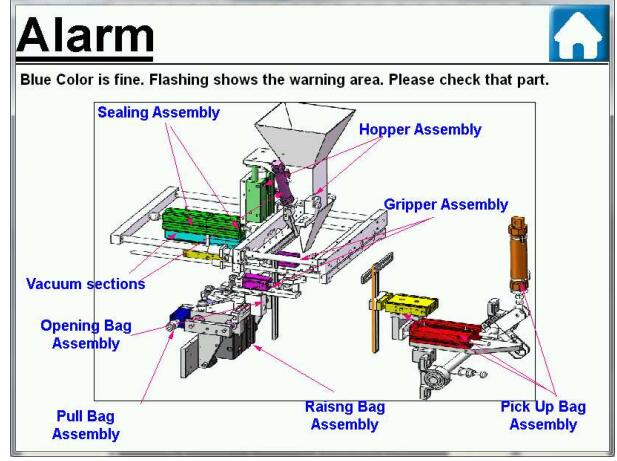

•Mini Doypack Machine

Technical parameter:

Packing Speed : 5-8 bags/min

Applications:

1.Humanism design, easy dismantle, no need any tools could dismantle the contact parts to clean,

2.No any dead angle could leave so very suit for grocery industry. This whole process only one person one minute will be finished, save labor and high efficiency.

3.The hopper with arch breaker device, help you to shoot bridge problem.

4.Update Device: Polished screw, side-opening tube.

Optional accessories:

1.Standard control box *Safety Net *Vibration Sieve *Hopper cover 2.Dust cover * Blender for anti-bridge.

| Model No. | JHZP-1 | JHZP-2 |

| Bag Width | 130-280mm | 130-300mm |

| Bag Length | 130-300mm | 130-400mm |

| Bag Type | Stand-up bag, pillow bag | Stand-up bag, pillow bag |

| Power Supply | 220V, 50HZ | 220V, 50HZ |

| Air Consumption | 7.0 CFM@80 PSI | 7.0 CFM@80 PSI |

| Pneumatic Parts | PIAB Vacuum Generator, Pneumatics component Airtac from Taiwan | PIAB Vacuum Generator, Pneumatics component Airtac from Taiwan |

| Technical Specifications | |||

| Model No | JHSC1 | JHSC2 | JHSC3 |

| Capacity | 3-5m3/h | 5-7m3/h | 8-10m3/h |

| Hopper Size | 230L | ||

| Discharging Height | ≤3000mm(optional) | ||

| Material | Stainless Steel 304 | ||

| A | 970mm | ||

| B | 910mm | ||

| Power | 3-phase 380V 50Hz,0.75-5.5KW | ||

| Machine Weight | 70-350Kg | ||

Unique hopper design is our one of scientific and technological achievements for studying many years in powder packaging industry, and access to national utility model patents, in line with GMP certification requirements

*There are economical and convenient hopper type can be selected. Economy model the cone hopper is one set, have to remove the cone then can be cleaned; convenient model: the front half hopper could be opened horizontally, as easy as opening doors and windows, cleaning faster and easier.

*Whole machine set used SUS304, waterproof motor (IP65), could wash with water, and meet the food industry requirements.

Optional Parts:*Spinner: suit for free flow product * Closure: suit for too free flow product* Dust Collector: suit for flying powder.

* Bag Clamping Weighing Function: suit for high accuracy requests, the accuracy could do ≤±2g

| Technical Specifications | |

| Model No | JHAF -350 |

| Metering Model | By auger or load cell feedback(optional function) |

| Dosing Range | ≤1000g |

| Dosing Accuracy | ± 0.3-1%(depend on actual product and speed) |

| Container Model | Can or Bag |

| Hopper | 25L |

| Filling Speed | Max: ≤20bags/min |

| Power & Output | Single-phase 220V 50/60Hz ,3KW |

| Machined Size | 780L*730W*1690Hmm |