Powder density (specific gravity) plays a very important role in powder mixing. The smaller the difference in powder density, the easier it is for powder mixing to proceed, while the larger the difference in powder density, the more difficult it is for powder mixing. Powder density also has an impact on powder flowability, and under the same conditions, the higher the powder density, the better the flowability.

1、 The concept of powder density (specific gravity)

The density of powder refers to the mass of powder per unit volume. In practical applications, the density of powders can be divided into loose density and compacted density.

1. Loose density: refers to the ratio of the mass and volume of naturally accumulated powder within a small dose volume unit, where the powder is loosely bound.

2. Vibration density: refers to the ratio of the mass to volume of a powder that has been repeatedly vibrated and compacted per unit volume, with the powder in a relatively tight bonding state. Usually, the compacted density is 1.2-1.3 times the loose density.

3. The actual density of the material in the bucket: In practical applications, the comprehensive density of the powder in the mixing equipment bucket is between the loose density and the compacted density. Therefore, when calculating the loading capacity of the mixing equipment, the influence of these two densities should be considered.

4. The relationship between powder specific gravity and powder density:

Density is the ratio of powder mass to volume (the measurement method of mass is very complex); The specific gravity is the ratio of powder weight to volume (the method of measuring weight is very simple). The specific gravity and density of powder are almost equal in low altitude areas near sea level. Therefore, we usually use specific weight to approximate density.

2、 The Effect of Powder Specific Gravity on Mixing

The specific gravity of powder is an important factor affecting the mixing process, which can be affected in the following ways.

1. The impact of specific gravity differences between powders on powder mixing:

1) The smaller the difference in specific gravity between powders under the same conditions, the easier it is to achieve uniform mixing. This is because uneven phenomena such as weight segregation are less likely to occur during powder movement;

2) The greater the difference in specific gravity between powders under the same conditions, the more difficult it is to achieve uniform mixing. This is because the heavier powder particles tend to sink during movement, while the lighter powder particles tend to float upwards, making it difficult for uniform mixing.

2. The influence of powder specific gravity on flowability can indirectly affect the difficulty of powder mixing:

1) The larger the specific gravity of the powder, the better its fluidity during mixing. This is because the increase in weight has an impact on powder movement.

2) Generally speaking, the better the fluidity, the easier it is for the powder to homogenize and mix.

Note: If the flowability of the powder is too good, it will actually bring difficulties to homogenization and mixing, and this issue will be discussed in terms of flowability.

3、 The typical mixing problem is that light and heavy powders are not easily mixed evenly

When there is a significant difference in the specific gravity of the powder, the problem of light and heavy powder being difficult to mix evenly arises.

Question raised:

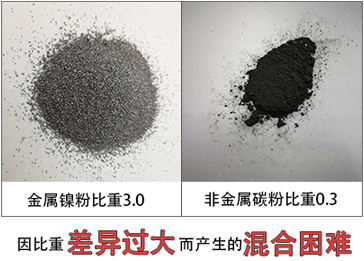

The above example is that in the powder metallurgy industry, the problem of mixing light and heavy powders is often encountered. Its classic representative is the addition of non-metallic carbon powder (alloying element) to metal powder, which has a significant metal powder ratio, usually between 1.0 and 3.0. Some tungsten powder even reaches 4.0 or above, and the specific gravity of carbon powder is about 0.3. It is difficult to evenly mix lighter and less abundant carbon powder into heavier metal powder during mixing. This is a typical problem of mixing light and heavy powders. In a moving mixing container, due to the fact that the specific gravity of light and fine carbon powder is much smaller than that of metal and other powders, some of the light powders remain suspended above the main powder and even float in the air. Without forced mixing methods, even if the mixing time is extended, it is difficult to mix them into the theme powder.

Solution:

Choose dual motion ® The mixer can also solve this problem well, due to the dual motion ® The mixing machine container rotates in the same direction as the internal blades, with different rotational speeds. In this way, the rotation of the material barrel can rotate the bottom heavy powder to the upper part of the powder body, and the binding effect of the full size spiral blades and the material barrel can mix the upper light powder into the main powder, thus allowing the light and heavy powder to be evenly mixed.