Understanding the mixing principle of powder and dry powder is the key to mastering the mixing process.

1、 Overview of Powder Mixing

In many industries such as pharmaceuticals, food additives, powder metallurgy, and chemical engineering, it is necessary to evenly mix various powders according to a certain formula ratio, and then process them into terminal products. During this process, the uniform distribution of various component powders has a direct and significant impact on the performance of the final product. The so-called mixing refers to the operation process in which the powder material undergoes changes in movement speed and direction under external forces (such as gravity or mechanical force), resulting in uniform distribution of each component particle.

2、 The principle of powder mixing

In a mixer, there are generally three ways of mixing materials:

1. Diffusion mixing - small-scale layered diffusion and movement of powder, where the separated powder moves to the constantly emerging layer under external force, enabling the diffusion of each component powder to achieve uniform distribution within a local range.

2. Convective mixing - Powder moves randomly on a large scale, causing a fluid like motion under external forces. The powder moves from one part of the material to another, achieving uniform distribution through convection over a large range.

3. Shear mixing - shearing the interior of a powder material group, causing mutual slip between powders under external forces, forming a slip surface, and continuously shearing the local powder to achieve uniform distribution.

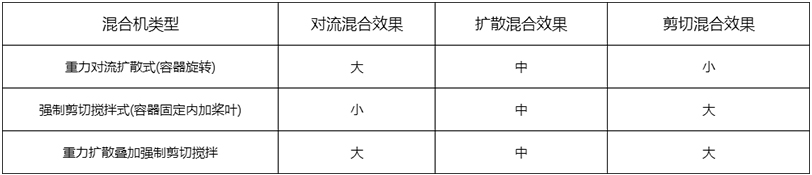

The above three mixing functions cannot be separated, and various mixers are dominated by one of the above three functions. Due to different structures, there are significant differences in the mixing effects of various mixing equipment (see the table below).

3、 Mixing Principles in Mixing Equipment

During the entire mixing process, whether it is manual mixing or mechanical equipment mixing, according to the working principle, it can be divided into two types: gravity convection diffusion type mixing and forced shear stirring type mixing.

1. Gravity Convection Diffusion Mixing Principle

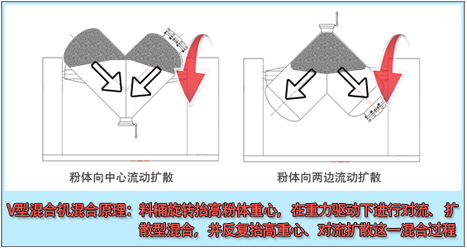

A mixing method in which the center of gravity of the powder is continuously raised by mechanical force, and gravity is used to force the powder to repeatedly flow, diffuse, hedge, fold, and other movements downwards. Its function is to blend and penetrate between powders at a macro level, thereby achieving the goal of uniform mixing. Representative models: V-type mixer, 3D mixer, double cone mixer, etc.

The following figure shows the mixing principle of the V-type mixer:

From the above figure, it can be seen that the macro convection of the powder material in the V-type mixer is fast and efficient, while the micro particle displacement and exchange inside the powder are slow.

2. Principle of Forced Shear Stirring Mixing

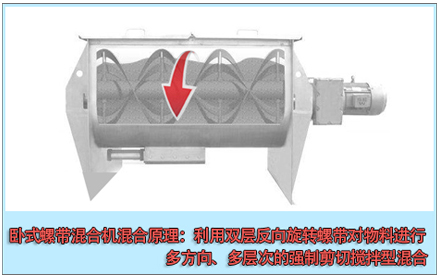

A mixing method that utilizes the moving blades inside the container to force repeated mixing, shearing, and other movements of the powder. Its function is to continuously break up the adjacent relationships between powder particles at the micro level, allowing the powder particles to fully move and exchange, achieving the goal of uniform powder mixing. Representative models: slot type screw belt mixer, single cone screw mixer, and plow blade mixer.

The following figure shows the mixing principle of a horizontal screw belt mixer:

From the above figure, it can be seen that the powder material in the horizontal spiral belt mixer is subjected to forced shear stirring, and its microscopic powder particle displacement and exchange are fast and efficient. However, the overall macroscopic movement of the material in the barrel is relatively slow (it takes a longer time for the material on the left side of the barrel to move to the right).

3. A mixer that combines the principles of gravity diffusion mixing and forced shear mixing

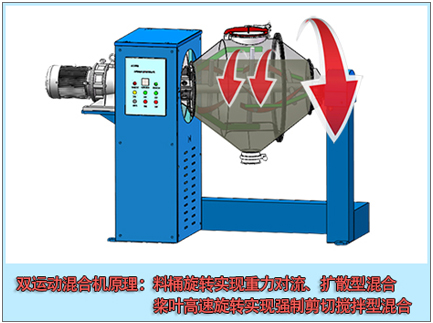

If a mixer combines the principles of gravity diffusion mixing and forced shear mixing, it is a very ideal mixing model. This type of machine can leverage the advantages of gravity diffusion type mixing, such as macroscopic convection and efficient diffusion, as well as the advantages of forced shear type mixing, such as displacement and exchange between particles at the micro level, and sufficient dispersion.

Current dual sports in the market ® A mixer is a mixer that combines these two mixing principles.

The following figure shows dual motion ® The mixing principle of the mixer:

The figure can reflect dual movements ® The mixer uses both gravity diffusion type mixing and forced shear type mixing as its main mixing methods, so it has the advantages of macroscopic rapid flow and diffusion of powder, and microscopic forced rapid displacement, exchange, and dispersion. Thus, it has good results in both mixing efficiency and mixing uniformity.

In practical work, hybrid equipment is mainly implemented to achieve a certain mixing principle, but it will also be accompanied by the occurrence of other mixing principles.