1、 Question raising

In actual powder mixing processes, various agglomerate structures, also known as pseudo particles, are often encountered in the powder. The formation reason is the formation of pseudo large particle structures (referred to as pseudo particles) formed by viscous adhesion, adsorption, and solidification. Some large particles are composed of clustered fibrous tissue.

According to the different binding forces, they can be divided into loose type pseudoparticles and tight type pseudoparticles. The former can be dispersed by gentle touch, while the latter requires strong pressure to disperse.

2、 How to Mix Powder Containing Fake Particles Evenly

Pseudoparticles can be classified into the following categories based on their internal binding force, and targeted treatment can be carried out accordingly:

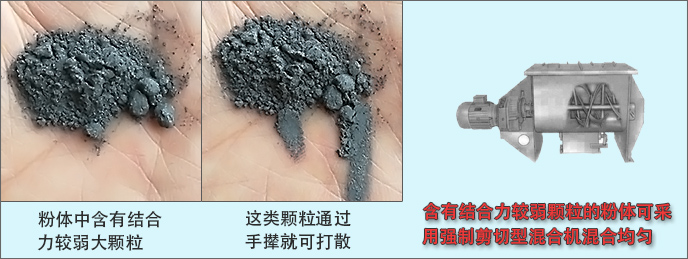

1. For loose pseudoparticles with weak binding force

Mixing equipment with forced shear mixing function can be used. During the mixing process, the use of forced shear motion blades can disperse loose pseudo particles, ensuring smooth mixing. Refer to the following figure:

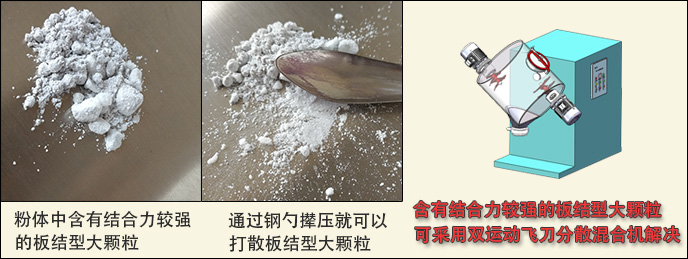

2. For compact fake particles with strong binding force

A mixing device with high-speed flying knife dispersion function can be used. During the mixing process, a flying knife with thousands of revolutions is used to forcefully break up dense pseudo particles, enabling both breaking up and mixing to proceed smoothly. Refer to the following figure:

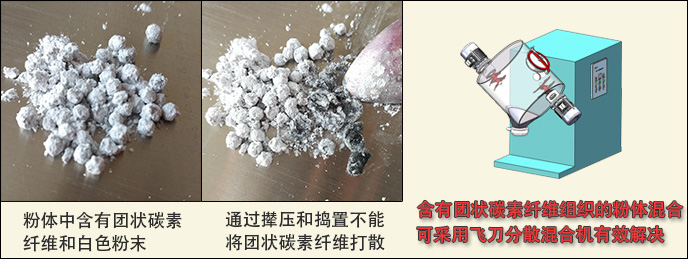

3. For fake particles composed of clustered fibers

Dual motion with rotating flying blades available ® Flying Knife Dispersal Mixer. Using high-speed rotating flying knives to strike clumps of fibers, the fibers are dispersed and powder is filled between the fibers to avoid secondary entanglement. This effectively solves the problem of uniform mixing of clustered fibers and powders. Refer to the following figure:

The above image shows a mixture of white powder and black carbon fibers in clusters. The carbon fibers are tightly intertwined and are not easily broken up by pressing and tamping. However, the black clumps of carbon fibers can be opened by a high-speed rotating flying knife with a speed of 1000 revolutions per minute, ultimately achieving the goal of uniform mixing.

4. For fake particles with particularly strong adhesion (such as mortar stones)

Neither the forced shear mixer nor the flying knife dispersion mixer can disperse such hard particles. It is necessary to use grinding and crushing equipment to forcibly crush into powder, and then add a mixer to participate in mixing.

Ball mill machine in below picture: