Fluidity plays an extremely important role in powder mixing, and in general, the better the fluidity, the faster the mixing process; In extreme cases, having too much liquidity can actually hinder the mixing process. Therefore, we need to conduct in-depth exploration of convection.

1、 What is liquidity

The ability of powder to undergo displacement under the action of force.

Explanation: Refers to the performance of powder flow during mixing motion.

2、 Representation method for powder flowability

The simplest way to represent fluidity is to use powder stacking angles.

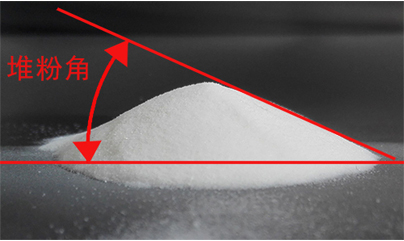

1. Powder stacking angle (angle of repose/angle of repose)

The angle between the inclined plane and the horizontal plane of the cone after natural accumulation of powder indicates the fluidity of the powder. The higher the angle, the better the fluidity of the powder.

Explanation: The angle of repose, also known as the angle of repose, refers to the angle between the inclined plane and the horizontal plane of the powder surface when the powder is poured onto a flat surface and allowed to flow around and stabilize. In practical applications, the stacking angle is usually used to represent the flowability of powder, because this method is easy to operate and intuitive. The smaller the inclination angle, the better the fluidity, and vice versa, the worse the fluidity as shown in the figure below.

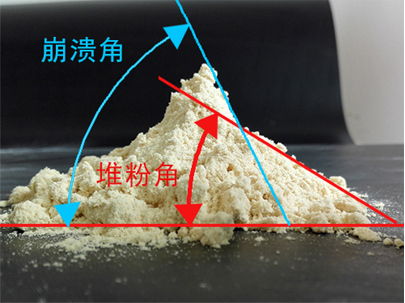

2. Powder collapse angle

Only when the fluidity of the powder is particularly poor will the powder collapse angle occur.

During the process of powder accumulation, due to poor flowability, there will be a phenomenon of continuous pile up - collapse, collapse, and then pile up - collapse, collapse. The angle between the cross-section left by the powder after collapse and the horizontal plane is called the powder collapse angle, as shown in the following figure.

Explanation: Usually, only powders with poor fluidity will have a collapse angle; Powders with poor flowability usually have both a collapse angle and a powder stacking angle, where the upper part produces a collapsed angle and the lower part produces a flowing powder stacking angle.

3. Factors affecting liquidity

① Shape of powder particles: The closer the shape of powder particles is to a circular shape, the better the flowability of the powder. The more complex the shape of powder particles (such as dendritic), the worse the flowability;

② Surface smoothness of powder particles: The smoother the particle surface, the better its fluidity; the rougher the particle surface, the greater its flow resistance, and the poorer its fluidity;

③ Adhesion and adsorption between powder particles can also lead to poor fluidity.

4. Liquidity is a double-edged sword

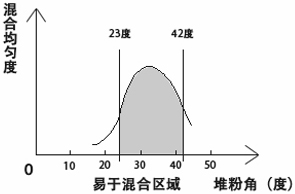

Poor flowability and particularly good flowability can both affect the process of uniform mixing, and only powders with flowability between 25 and 42 degrees are suitable for smooth mixing. As shown in the following figure:

① The fluidity is located in a region that is easy to mix (as shown in the figure above), making it particularly suitable for smooth and uniform mixing.

② Powder with poor fluidity, such as a powder stacking angle greater than 42 degrees, slows down the process of uniform mixing during mixing due to the high friction between powder particles, greatly prolonging the mixing time and even failing to achieve the goal of uniform mixing.

③ Powders with particularly good fluidity, such as those with a stacking angle of less than 23 degrees, may experience segregation between heavy and light powders, as well as large and small particles, due to the low friction between the powder particles during mixing. The result is that it is difficult to achieve uniform mixing.