1、 Question raising

Excessive fluidity usually occurs in the mixing of metal powders. Excellent fluidity can also bring mixing difficulties. In principle, the better the fluidity of the powder, the higher the mixing efficiency of the powder. According to the theory of liquid mixing model, the faster the flow speed of the powder, the higher the mutual mixing and permeability efficiency of the powder, making it easy to achieve the goal of uniform mixing. However, in practical applications, the following adverse issues may arise:

1. According to the theory of liquid mixing model, during the mixing process of powder, due to the good fluidity of the powder, it will strengthen the phenomenon of new floating or sinking due to the differences in powder characteristics;

2. Even after uniform mixing, the powder is prone to secondary segregation and layering under the vibration environment of loading, unloading, and transportation, resulting in new unevenness.

2、 Definition of Excellent Liquidity

Powder flowability refers to the ability of a powder to move under the action of force. The fluidity of the powder is excellent, and the holding force between the powder particles is insufficient. During the mixing process, there is a phenomenon of segregation as soon as the powder is evenly mixed, and segregation occurs alternately as soon as the powder is evenly mixed. Mainly influenced by particle size, particle shape, and interaction between particles.

1. Specific gravity effect

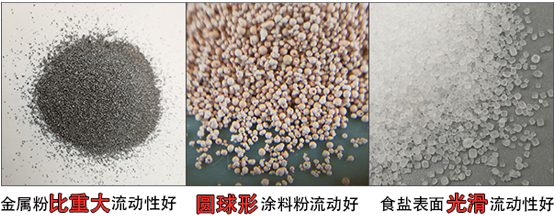

The larger the specific gravity of the powder, the greater the gravitational effect, and the greater the flow trend of the powder under the gravitational effect. Therefore, the larger the specific gravity of the powder, the better its fluidity.

2. Particle shape effect

Due to the minimum rolling resistance of spherical objects, the closer the particle shape of the powder is to a spherical shape, the better its flowability.

3. The Smoothness Effect of Particle Surface

The smoother the surface of powder particles, the smaller the frictional force between them, and the greater the fluidity exhibited by the powder.

Summary: If the specific gravity of the powder is large, the particle shape is similar to a spherical shape, and the surface is smooth, there will be a phenomenon of excellent fluidity, which brings difficulties to uniform mixing.

3、 Solution

Solve the mixing problem caused by poor fluidity by changing the original shape of the material or selecting high-end mixing equipment.

1. Breaking the powder to change its shape and surface smoothness

The shape and surface smoothness of the powder particles can be changed by crushing them, thereby reducing the flowability of the powder and achieving uniform mixing.

2. Friction additives can be added to reduce flowability

For example, adding friction aids such as paraffin to metal powder materials greatly reduces the flowability of the metal powder, ensuring smooth and uniform mixing. (During the subsequent sintering process of metal workpieces, all paraffin will evaporate and have no impact on the mechanical properties of the metal)

3. Choose high-end dual sport hybrid equipment

Dual motion ® The movement characteristics of the mixing equipment are: firstly, it adopts medium to low speed operation to reduce the powder flow speed, weaken its fluidity, increase the holding force between powder particles, and reduce the activity of powder particle movement; The second is that the rotating motion of the material barrel always mixes the material at the bottom and the material at the top of the barrel upside down, preventing the segregation phenomenon caused by poor fluidity.