In powder mixing work, we often encounter powders with poor flowability (such as wheat flour), which are difficult to achieve uniform mixing using commonly used V-shaped machines and three-dimensional mixers. The reason is that the mixing principle of this mixer is gravity convection diffusion type, and poor fluidity of the powder leads to slow flow and diffusion of the powder, slowing down the process of uniform mixing. If a trace amount is added to a powder with poor flowability, it becomes more difficult to mix evenly.

1、 Definition of poor liquidity

The flowability of powder is the ability of the powder to move under the action of force, which can also be said to be the performance of the powder's flow speed during movement. The fluidity of the powder is one of the main reasons determining whether the mixing task is successfully completed.

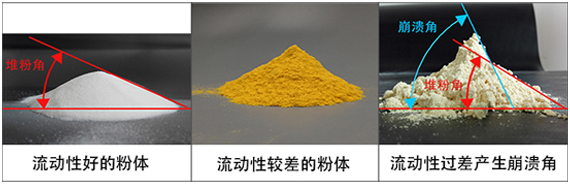

The flowability of powder is usually represented by the angle of powder stacking on a flat surface, as shown in the following pictures of powder with good flowability, poor flowability, and poor flowability:

When the powder stacking angle is large, the fluidity of the powder begins to deteriorate. When the powder stacking produces a collapse angle, it indicates that the powder fluidity is too poor. Powders with collapse angles are not easily mixed uniformly in the mixing process.

2、 How to mix powders with poor fluidity

1. For powders with poor fluidity, the mixing principle of forced shear can be used for mixing

Due to the poor flowability of the powder, the slow flow and diffusion of the powder affect the normal mixing process. The stirring blades can be used to forcibly shear and stir the powder, forcing the flow, shear, and position change of the powder particles, thereby overcoming the mixing difficulties caused by poor flowability.

Adopting the principle of forced shear mixing for powders with poor fluidity can also improve mixing efficiency and shorten mixing time.

2. Using a ribbon mixer to mix powders with poor flowability

Ribbon mixer is a mixer that adopts the principle of forced shear mixing. Mixing powders with poor flowability can achieve uniform mixing and improve mixing efficiency.

Due to the fixed material barrel of the screw belt mixer, there are some disadvantages such as a small amount of dead corners and inconvenient discharge of materials.

3. Adopting dual motion ® Mixer mixes powders with poor fluidity

Dual motion ® The mixer is a mixer that adopts the principle of forced shear mixing, and also has the ability of gravity diffusion mixing. For powder dual motion with poor fluidity ® The mixer can achieve the goal of uniform mixing and high mixing efficiency.

Due to double movement ® The mixer adopts the principle of forced shear superimposed gravity diffusion mixing, so it does not have the aforementioned drawbacks of screw belt mixer, namely no dead corners of materials and convenient discharge.

3、 The duality of things - powders with poor fluidity have a good characteristic

A good characteristic of powders with poor fluidity is that once the materials are evenly mixed, the powder will no longer exhibit secondary non-uniformity such as segregation. This is because the fluidity between powder particles is poor and the friction force is high, and even in intense motion, there will be no segregation between weight and size.

Usually, powders with poor flowability can improve mixing uniformity by extending the mixing time, but doing so will increase costs.