The basis for selecting mixing equipment is: firstly, select targeted mixing equipment based on the basic characteristics of the materials to be mixed;

The second is to select mixing equipment with different mixing capabilities based on the requirements for mixing uniformity.

1、 Select a forced shear stirring mixer for powders with poor fluidity

1. Analyze the cause

In the field of food, powders with poor fluidity are often encountered because the particles inside the powders move slowly, which affects the mixing effect. A stirring blade is required to perform forced shear stirring inside the powder to overcome the mixing difficulties caused by poor fluidity.

2. Its representative model

Single cone mixer, spiral belt mixer

Advantages: High mixing efficiency; Microscopically, the powder particles are relatively uniform.

Disadvantages: Mixed with dead corners; High energy consumption of equipment.

For the powder situation, the equipment is required to have performance such as good mixing uniformity, no dead corners, high mixing effect, and low power consumption.

The mixing equipment is required to not damage the physical indicators of the powder, such as the specific gravity, average particle size, and particle surface shape of the powder.

It also requires the mixing equipment to operate safely, operate conveniently, save electricity, and labor.

2、 Gravity convection diffusion mixer can be selected for powders with good flowability

1. Analyze the cause

When mixing metal powders with good fluidity, V-shaped machines, three-dimensional machines, etc. are often used. This is because the powder has good flowability, and its convective diffusion speed will be fast and efficient. Using a convective diffusion type mixer can leverage the advantages of high mixing efficiency of the mixer.

2. Its representative model

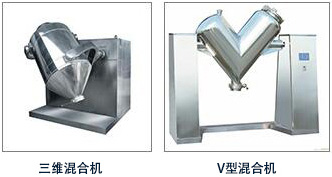

3D mixer, V-type mixer

Advantages: Mixed without dead corners; Macroscopically, the powder in each part of the container is uniform and consistent.

Disadvantages: Insufficient uniformity of powder particle mixing at the micro level; The mixing effect is low.

3、 Adopting a mixer with high mixing performance for mixing tasks with difficulty in uniform mixing

1. Efficient mixer must be selected for powders that are difficult to mix evenly

These difficulties include particularly poor liquidity; It is difficult to mix light and heavy powders; Ultra light powder and ultrafine powder are difficult to mix; Due to the difficulty in mixing trace elements, an efficient mixer that combines the principles of gravity convection diffusion and forced shear stirring can be selected.

Utilize the improvement of the mixing ability of the mixer to overcome the aforementioned difficulties encountered in mixing.

2. Its representative model

Double movement ® Mixer

Advantages: High mixing uniformity, able to achieve macroscopic and microscopic uniformity; High mixing efficiency; High material loading rate; Low energy consumption.

Disadvantages: The equipment structure is relatively complex, and the procurement cost is relatively high.