Most normal powders can be directly mixed, but there are also many powders with special characteristics that are not suitable for direct mixing. This is because of the special nature of powders, and without pre-treatment, the goal of uniform mixing cannot be achieved.

1、 If there are the following special powder characteristics, targeted process treatment is required before mixing:

1. Powder hardening or false particles require pre-treatment before participating in mixing

Long term placement, humidity, or electrostatic adsorption of powders can result in the formation of large or small clumps or pseudo particles (agglomerates) within the powder body. Such powders require pre-treatment to participate in mixing. There are various methods of pre-treatment, with the aim of crushing the hardened material and false particles to meet the conditions for dry powder mixing. 2. If there are too large particle sizes or too heavy powder particles in the powder, pre-treatment should also be carried out to meet the mixing conditions

This is because oversized or overweight powder particles in the powder tend to sink during mixing and settle to the bottom, making it difficult to mix evenly. The method of pre-treatment is to grind them fine, which can reduce their particle size and powder specific gravity, thereby eliminating their sinking motion trend and ensuring smooth mixing. 3. Powders with good or poor flowability can also be added with additives to improve their flowability and meet mixing conditions

For example, adding additives such as paraffin to iron powder with excellent flowability can appropriately reduce the flowability of the iron powder, thereby ensuring smooth and uniform mixing. 4. If the powder participating in the mixing meets good mixing conditions, there is no need for pre-treatment

For example, if the particle size and specific gravity of the powders involved in mixing do not differ significantly, and their flowability is moderate, such powders do not require pre-treatment and can directly participate in mixing. 2、 Example: The necessity and scientificity of pre-treatment before mixing.

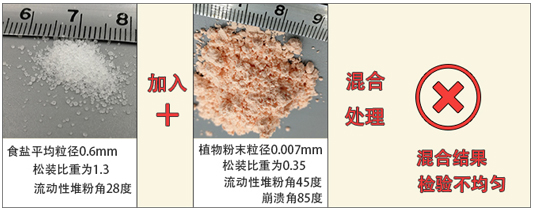

Taking the mixing of table salt and plant powder as an example, as shown in the following figure:

The mixed results are displayed unevenly, and the reason is analyzed as follows:

Firstly, the particle size of table salt is dozens of times larger than that of plant powder, and the large difference in particle size affects the uniform mixing of the powder;

Secondly, the specific gravity of table salt is nearly 4 times that of plant powder, and the difference in specific gravity is too large, which affects the uniform mixing of the powder;

Thirdly, the surface of salt particles is smooth, with good fluidity, and they are prone to segregation and sedimentation during mixing.

The combined effect of the above three reasons leads to mixing failure. If the basic characteristics of table salt are changed and the above three unfavorable factors are eliminated or reduced, the uniform mixing can proceed smoothly. This requires pre mixing crushing pretreatment for table salt, changing its particle size, specific gravity, and surface smoothness to make its powder characteristics similar to plant powder and achieve the basic conditions before good mixing.

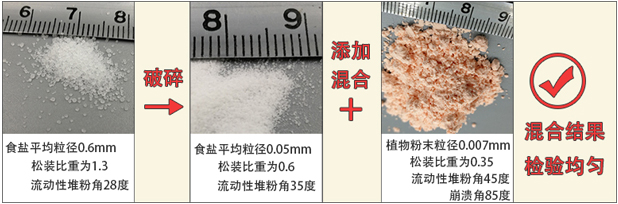

The following figure shows that salt is first crushed and pretreated, and then plant powder is added for mixing:

The experiment in the above figure shows that first crushing the salt that does not meet the mixing conditions reduces its particle size by 91%, loose weight by 52%, and fluidity. Then, mixing the salt with plant powder can obtain a uniform and qualified mixing result.