Light powder, ultra light powder, micro powder, nano powder and ultra-fine powder all have a common property - floatability. The floatability of light powder is due to its "lightness" and small gravitational constraints that cause it to float; The floatability of micropowder is because it is too small, resulting in being very "light" and being constrained by gravity to float. Once the powder floats, it will cause the powder to not mix evenly.

1、 Question raising

In the daily mixing process, the light powder in the mixing bucket encounters mechanical kinetic energy and floats, causing difficulties in mixing. Light powder and ultra light powder have always been a challenge in the mixing process. The reason is that when the light powder is "light" to a certain extent, the kinetic energy obtained during movement overcomes its own gravitational binding effect and floats in the air, making it difficult for ordinary mixing mechanical forces to apply, making it difficult to mix and even extending the mixing time cannot achieve the mixing purpose.

To address this issue, we need to do two things: first, control the intensity of the movement and reduce the trend of light powder flying; The second is to design a mixer with the ability to press down and carry light powder into the main powder.

For example, using a 3D mixer to mix a batch of materials containing light powder and ultra-light powder, after the mixing is completed and left to stand for a period of time, opening the feeding port to observe, it is found that a layer of ultra-light powder will clearly float off the main powder, indicating that the ultra-light powder has not been completely mixed into the theme powder, even if the mixing time is extended, this problem still exists.

2、 Definition of Ultra Light Powder

Light powder refers to powder with a specific gravity of 0.1-0.3, while ultra light powder refers to powder with a specific gravity of less than 0.1, such as carbon powder. In a single gravity diffusion mixing process, due to the light weight of the powder, gravity can no longer constrain its own floating characteristics. By slightly increasing the mechanical kinetic energy, the light powder will float in the air, causing difficulty in uniform mixing.

3、 Solution

In response to the characteristics of light powder and ultra-light powder that are difficult to mix evenly due to floating, a mixing equipment with the ability to forcibly mix light powder and ultra-light powder into the main powder should be selected.

Select the following types of mixers for light and ultra-light powder mixing experiments.

The three types of powders participating in the experiment are: A resin with a specific gravity of 0.2, B resin with a specific gravity of 0.35, and pigment powder with a specific gravity of 0.1

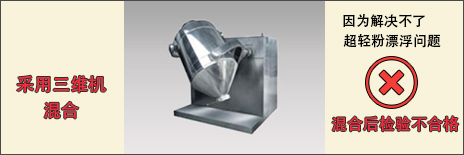

1. Using a 3D mixer for mixing

Mixing for one hour resulted in uneven test results. Analysis reason: The three-dimensional mixer belongs to the gravity diffusion type mixer, with a loading rate of about 50%, and there is still 50% convective diffusion space in addition to materials, which is easy to retain floating light powder. During the mixing process, the phenomenon of light powder pigment floating during movement is severe, leading to mixing failure.

2. Mixing using a horizontal spiral belt mixer

Mix for one hour, but the mixing result is uneven. Analysis reason: The horizontal spiral belt mixer belongs to the type of forced shear mixer with moving blades. During the mixing process, when light powder and ultra-light powder are stirred by moving blades, they are easily floating above the material in the bucket due to their small specific gravity, making it difficult to achieve uniform mixing.

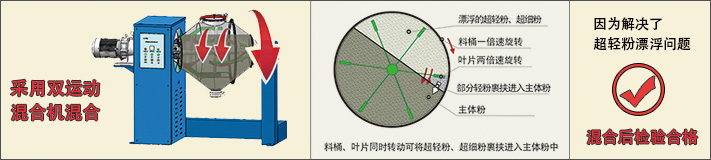

3. Adopting dual motion ® Mixer mixing

Mix for one hour and the mixing result is qualified. Analysis of reasons: Firstly, dual motion ® The rotation of the mixing machine barrel and forced mixing of the blades belong to medium and low speed operation, which is not easy to cause light powder to float; The second is dual movement ® The loading rate of the mixer is as high as 80%, leaving limited space for the floating of light powder and ultra-light powder; The third is dual movement ® The rotation of the mixing machine bucket and the rotation of the blades can simultaneously bind the floating light powder and ultra-light powder into the main powder.

Summary: Through the above examples, it is demonstrated that the main difficulty in mixing light powder and ultra-light powder lies in its dynamic floating phenomenon. Only by overcoming this phenomenon can the mixing be evenly and smoothly carried out, with dual motion ® The mixer has the ability to overcome the floating of light powder in this way, in order to achieve the goal of evenly mixing light powder and ultra-light powder.